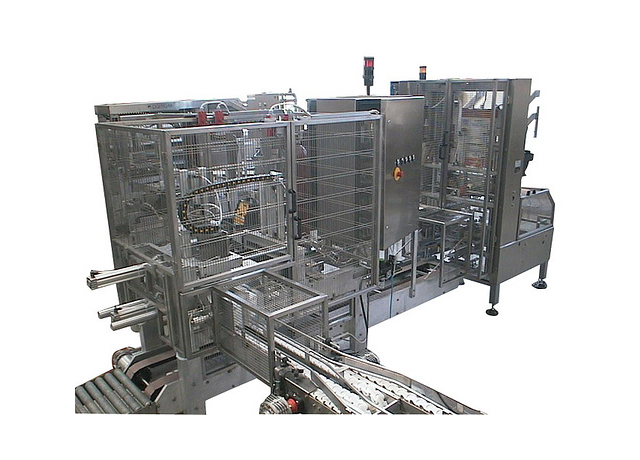

Automatic machine, suitable to handle packs such as brik, combibloc and similar ones, moving on two independent rows. This machine allows to keep separate the product coming from the two lines.

Framework realised in stainless materials;

Empty tray conveyor, also operating as tray accumulation conveyor;

Pack infeed, on two independent lanes, carried out by conveyors, with thermoplastic resin cardan chain, driven by geared motor;

No. 2 pack preparation groups, each one is fitted with brake, spacer and preparing device;

No. 2 transferring units, moving the complete pack from the preparation area to the tray feeding conveyor;

Machine infeed conveyor with step-by-step movement, fitted with frequency converter to start and stop on controlled speed;

Pushing unit, moving the pack to the filling area;

Horizontally moving hiding platform;

Tray centering hopper during the filling operation;

Tray lifting device;

Pneumatic device, introducing the pack into the tray;

Stainless steel electric panel; driven by PLC unit;

Accident-proof protections, realised according to European regulations, having gates, fitted with safety micro-switches;

Electric installation having IP 55 protection degree.

Output: 12.000 packs/hour, with 16/32 pcs trays

Voltage: 380 V.-50 Hz 3ph + N+ earth

Inst. el. power inst.: 8 kW

Compr.air cons.: 40 Nm3/h

Oper. pressure: 6 bar

Dimensions: 3800 x 4500 x H= 2000 mm

Weight: 1450 Kg approx