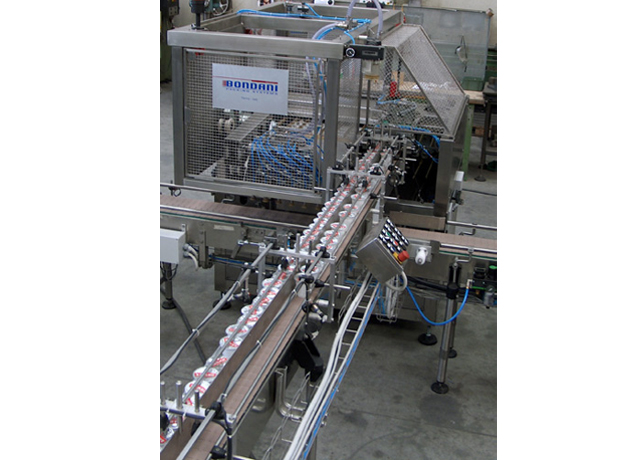

Automatic machine for filling trays with single or cluster-packed cups. Double lane infeed.

Structure in stainless steel tubular;

Empty tray conveyor belt on double lane, with table-top chain conveyor;

Braking device for timing the incoming packs;

Chain conveyor with step-by-step movement obtained through intermittance device for building-up the cup layer;

Empty/filled tray table-top conveyor, total length about 4 mt;

Stopping and centering devices for the trays in filling position;

Suction extraction head to pick-up the cups to be put into the tray; vacuum generated by means of Venturi unit;

Mobile device to compensate height difference between the two cluster packages;

Head moving system obtained through rack pinion, controlled by means of rod and handle device, synchronised with the chain conveyor;

Electronic cam programmer;

Electrical installation with safety degree IP 55 and PLC controlled electric board;

Safety at work guardings according to current regulations, complete with microswitch controlled hatches;

Fixed protections in stainless steel.

Max. output: 18.000 cups/h

El. power installed: 9 kW

Compr.air consumption: 16,5 Nm3/h

Weight: 1650 Kg. approx

Dimensions: 5820 x 1900 x H= 2200